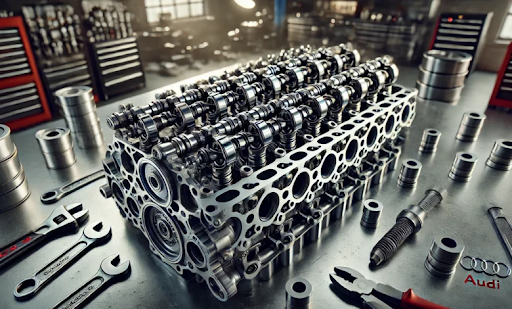

Mastering the Audi 5 Cylinder 10V Turbo Valve Shims: The Complete Guide for Performance Tuning

If you’re diving into the intricacies of the Audi 5 cylinder 10v turbo valve shims, you’re likely already deep into performance tuning or rebuilding one of Audi’s most legendary engines. The 10-valve inline-five turbocharged engine has long held a cult following due to its unique sound, rugged power delivery, and rally pedigree. But if your valve train isn’t precisely tuned with the correct valve shims, all that potential performance could go to waste.

Let’s walk through a deep-dive guide into how the valve shims on this classic powerplant play a critical role and what you need to know to keep your engine running at peak efficiency — or unlock its true racing spirit.

What Are Valve Shims in the Audi 5 Cylinder 10V Turbo Engine?

Valve shims are thin metal discs that sit between the camshaft and the valve tappets (also called lifters or buckets). Their purpose is to maintain the correct valve clearance — the small gap between the camshaft lobe and the valve mechanism. In engines like the Audi 5 cylinder 10v turbo, which use solid lifters, the precision of this gap is vital for smooth operation, especially under boost and high-RPM load.

If the clearance is too tight, the valve may not close completely, causing power loss or valve burning. If the clearance is too loose, you’ll hear tapping, and the cam may wear prematurely. That’s where valve shims come in — they allow fine-tuning without replacing the whole lifter.

Understanding Valve Shim Sizing and Fitment

The Audi 5 cylinder 10v turbo engine, typically designated as the MC, WX, or WR engine codes, uses solid bucket tappets with interchangeable shims for adjustment. These shims are available in a wide range of thicknesses, usually from 2.50 mm to 4.50 mm, in 0.05 mm increments.

How to Measure and Adjust Valve Clearance

- Warm up the engine to operating temperature, then let it cool slightly for safety.

- Remove the valve cover and rotate the engine to TDC (Top Dead Center) for each cylinder.

- Use a feeler gauge to measure the gap between the cam lobe and the shim.

- Compare to factory spec — usually around 0.20 mm (intake) and 0.40 mm (exhaust).

- If the clearance is out of spec, remove the cam and use a shim tool to pop out the current shim.

- Measure the current shim with a micrometer and calculate the new required thickness.

- Install the new shim and reassemble.

Note: Always rotate the engine by hand after reassembly to confirm no valve contact.

Why Valve Shims Matter in Turbocharged Applications

The turbocharged Audi 5-cylinder 10V engines see significantly higher combustion pressures than their naturally aspirated counterparts. This increases stress on the valvetrain. If your valve clearances are not correct:

- Valve float can occur at high RPMs.

- Valve lash may reduce compression and boost response.

- Cam wear accelerates if shims are misaligned or incorrectly sized.

Performance tuning — especially when upgrading the turbo or increasing boost — makes precision in valve shim sizing non-negotiable.

Selecting the Right Valve Shim Material and Brand

Aftermarket and OEM-quality shims differ in material and tolerance. When sourcing valve shims for the Audi 5 cylinder 10v turbo, look for the following:

- Hardened steel construction

- Tolerance within ±0.01 mm

- Compatible with high-RPM solid lifter engines

Recommended brands include:

- Febi Bilstein

- INA

- Supertech

- OEM Audi/VW (if available)

Avoid no-name shims, especially from unverified online sources. Inferior materials will deform or wear quickly under turbocharged stress.

Common Valve Shim Issues and Symptoms in Audi Turbo Engines

When the valve shims are incorrect or wearing unevenly, several symptoms can appear:

- Ticking noise from the top end

- Loss of power or boost pressure

- Misfiring at high RPMs

- Backfiring or erratic idle

- Excessive valvetrain wear

Catch these early during regular maintenance. The Audi 5-cylinder turbo engine thrives when maintained with precision.

Waste Gate Spring and Valve Shim Synergy

Now, let’s talk about waste gate springs and how they interact with the valvetrain indirectly. A stiffer waste gate spring delays the waste gate valve from opening, allowing the turbo to build more boost. While this is excellent for power, it also:

- Increases cylinder pressures

- Elevates valve temperatures

- Adds stress to valve shims and tappets

That’s why, if you upgrade your waste gate spring or tune your boost controller, you must revisit your valve shim clearance. Overboosting without adjusting the valvetrain is a shortcut to catastrophic failure.

Performance Tips for Valve Shim Tuning

Here’s how experienced builders get the most out of their Audi 5 cylinder 10v turbo valve shims:

1. Use a Valve Shim Kit

Purchase a full shim kit with varying sizes so you don’t need to wait for parts mid-build.

2. Match with Camshaft Specs

Aggressive cams require specific clearances. Match shim sizing with your camshaft manufacturer’s recommendations.

3. Check Clearances Frequently

After a few thousand boosted miles, re-check valve lash. Shims can settle or wear.

4. Upgrade Buckets if Needed

If you’re running very high boost (20+ psi), consider hardened or coated buckets to reduce wear under shim pressure.

Rebuilding the 10V Turbo Head: Don’t Skip the Shims

When rebuilding the head on an Audi 5-cylinder turbo, always include shim selection in your parts list. Many skip this step, assuming old shims will fit. But each valve seating depth changes during machining — even new valve seats require custom shim adjustment.

A high-performance rebuild should include:

- New valve guides and seats

- Custom valve lash adjustment using micrometer-shim fitting

- Dialing in cam timing and valve lift for turbo spooling efficiency

Tuning Around Valve Shim Behavior

Your valve shim setup affects how the engine breathes. Tuners often ignore this, focusing on ECU mapping alone. But by adjusting valve clearance:

- You can shift powerband slightly (tight lash = earlier valve opening)

- Reduce turbo lag (better breathing = faster spool)

- Increase durability at high RPMs

It’s a tuning secret rarely discussed, but incredibly powerful when chasing every ounce of boost efficiency.

Final Thoughts: Take Valve Shims Seriously

The Audi 5 cylinder 10v turbo valve shims might seem like a minor detail, but they’re crucial in getting your engine to perform at its best. Whether you’re chasing horsepower figures on a dyno, trying to bring a Group B-era machine back to life, or just ensuring long-term durability on your turbo setup — precision here pays off.

Get your clearances dialed in, choose the right shim material, and revisit lash settings regularly as part of your maintenance or tuning routine. It’s a small part with a big impact — don’t overlook it.

FAQs About Audi 5 Cylinder 10V Turbo Valve Shims

Q1: What are valve shims in an Audi 5 cylinder 10V turbo engine?

A: Valve shims are thin metal discs used to adjust the clearance between the camshaft and valve tappets. They ensure proper valve timing and engine performance.

Q2: Why is valve clearance important in turbocharged engines?

A: Proper clearance prevents valve damage, improves boost response, and ensures smooth engine operation under high pressure and RPM.

Q3: How often should valve clearances be checked?

A: It’s recommended to check every 15,000 to 30,000 miles or after engine modifications or high-boost tuning.

Q4: Can incorrect valve shims affect performance?

A: Yes. Incorrect shim thickness can lead to valve float, power loss, or engine knocking.

Q5: Are aftermarket shims safe to use?

A: High-quality aftermarket shims from trusted brands like INA or Supertech are safe and reliable if they meet OEM tolerances.

Stay in touch to get more news & updates on Hamrosolarllc!