The Role of PCBs in Modern Kitchen Appliances: Enhancing Functionality and Efficiency

In the age of smart homes and automated living, kitchens are undergoing a dramatic transformation. From microwave ovens and refrigerators to coffee makers and dishwashers, modern kitchen appliances are no longer simple mechanical tools—they are intelligent, responsive, and highly efficient devices. At the core of this technological evolution lies the Printed Circuit Board (PCB), an essential component that enables the functionality of nearly every electronic appliance.

This article explores the extensive role PCB play in modern kitchens, examining their applications, benefits, safety implications, and how they are paving the way for smarter and more connected homes.

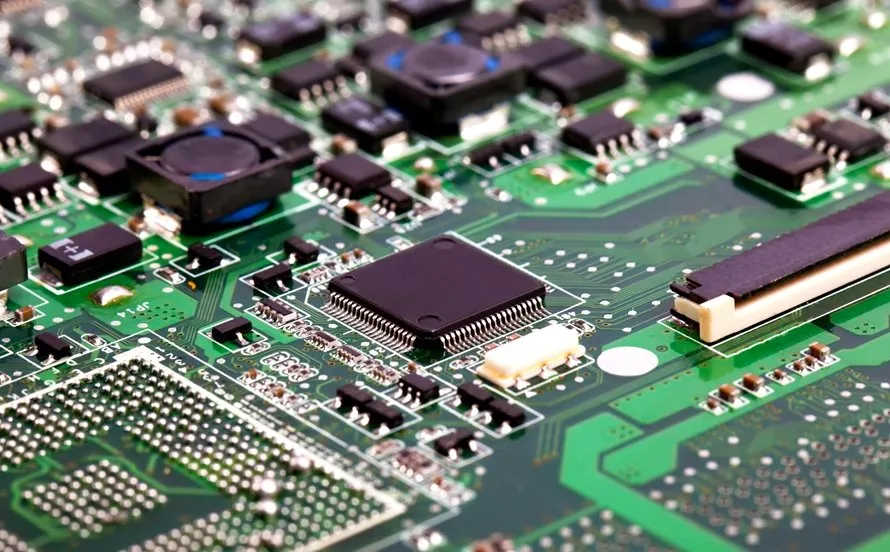

What is a PCB?

A Printed Circuit Board (PCB) is a flat board composed of insulating material (typically fiberglass) with conductive pathways etched onto its surface. These pathways—also called traces—connect various electronic components such as resistors, capacitors, diodes, and microcontrollers. The board provides both mechanical support and an electrical connection, enabling the entire appliance to function as intended.

PCBs come in various types:

- Single-layer PCBs (basic, used in simple devices)

- Multi-layer PCBs (complex, used in advanced electronics)

- Rigid and flexible PCBs (used depending on the design requirements)

Their application in kitchen appliances has revolutionized the way we cook, clean, and store food.

The Rise of Smart Kitchen Appliances

Over the past decade, kitchen appliances have transitioned from analog to digital systems. Traditional knobs and timers have been replaced by touch panels, digital interfaces, and even smartphone-controlled operations. This shift is entirely possible because of PCBs.

Key Trends Enabled by PCBs:

- Touch-sensitive controls

- Energy efficiency monitoring

- Sensor integration

- Bluetooth/Wi-Fi connectivity

- AI-powered operation

As a result, modern kitchens are becoming centers of innovation where PCBs form the backbone of intelligent functionality.

Common Kitchen Appliances That Use PCBs

Let’s take a closer look at how PCBs are integrated into various household kitchen devices:

1. Microwave Ovens

Microwaves use PCBs to control timing, power levels, and cooking modes. The control panel that allows you to set cooking time, defrost settings, and temperature is operated by a microcontroller embedded on the PCB. Sensors like humidity or temperature sensors are also connected through the PCB, helping ensure food is cooked efficiently.

2. Refrigerators

Modern refrigerators come with features such as temperature regulation, ice dispensers, digital displays, and even cameras inside the fridge. All these operations are handled by embedded PCBs. They allow for real-time temperature monitoring, compressor control, and user interface management. In smart fridges, PCBs also support Wi-Fi modules that let users control settings remotely.

3. Coffee Makers

High-end coffee machines with programmable settings, milk frothers, grinders, and touch panels rely heavily on PCBs. These circuit boards control everything from brewing time to water temperature and espresso shot customization.

4. Dishwashers

Dishwashers use PCBs to manage multiple wash cycles, water temperature, detergent usage, and drying modes. Sensors integrated into the PCB help detect the cleanliness of dishes, adjust water pressure, and prevent overflow.

5. Induction Cooktops and Ovens

Induction cooktops utilize complex PCBs for managing temperature settings, safety locks, and heat zones. The heat is controlled through an inverter circuit which is built into the PCB and responds to the user interface. These appliances also require rapid, real-time power adjustments, something PCBs handle with ease.

6. Air Fryers and Multi-Cookers

These multi-functional cooking devices offer digital timers, preset menus, and adjustable temperature settings. PCBs in these appliances control fan speeds, heating elements, and the operation logic behind cooking presets.

Benefits of Using PCBs in Kitchen Appliances

The widespread adoption of PCBs in kitchen appliances is not coincidental. These components offer several significant advantages:

1. Compact and Lightweight Design

PCBs allow complex electronics to be housed in a small form factor. This makes appliances sleeker, lighter, and more energy-efficient while maximizing performance.

2. Enhanced Functionality

With embedded microcontrollers, a single PCB can control dozens of features, including temperature, time, user interface, and safety mechanisms. It enables multi-functional appliances that cater to diverse cooking needs.

3. Smart Integration

PCBs are critical for adding IoT features, allowing kitchen devices to connect to home networks, voice assistants, or mobile apps. This integration has elevated user convenience and remote control possibilities.

4. Increased Energy Efficiency

Modern PCBs are designed to optimize energy consumption. Appliances can adjust their performance based on need, reducing power waste and enhancing longevity.

5. Improved Safety Features

Many PCBs come with fail-safe circuits and sensors to monitor appliance health. Overheating, electrical surges, or short circuits can be detected and countered instantly.

Challenges and Considerations

Despite their advantages, using PCBs in kitchen appliances poses several challenges:

1. Heat and Moisture Sensitivity

Kitchen environments are prone to moisture, oil, and heat—all of which can damage exposed PCBs. Manufacturers must ensure that these boards are well-insulated and protected through proper casing and conformal coating.

2. Repair Complexity

Unlike older mechanical systems, fixing a faulty PCB requires technical expertise. A minor failure in one component may render the entire appliance unusable, increasing repair costs.

3. E-Waste and Sustainability

As appliances become more electronic, they contribute to e-waste. Responsible design, recycling, and use of eco-friendly materials are essential for sustainable kitchen technology.

The Future: AI, IoT, and Beyond

PCBs are already enabling smart kitchens, but the future holds even more exciting possibilities.

AI Integration

With AI chips embedded into PCBs, appliances could learn cooking preferences, adjust automatically, and even suggest meals based on available ingredients. Imagine a fridge that recognizes what’s inside and recommends recipes.

IoT Ecosystems

PCBs will continue to power the seamless communication between kitchen appliances and digital assistants like Alexa, Google Home, and smartphones. You’ll be able to preheat your oven on the way home or monitor your dishwasher’s cycle remotely.

Edge Computing in Appliances

More advanced PCBs will allow for data processing within the appliance itself (edge computing), reducing the need for constant internet access and making devices faster and more secure.

Manufacturing and Design Standards

To ensure quality and safety, PCBs used in kitchen appliances must adhere to international standards such as:

- IPC-A-610: Acceptability of Electronic Assemblies

- RoHS Compliance: Restricts hazardous substances

- UL Certification: Safety for electrical devices

- ISO 9001: Quality management systems

Proper adherence ensures that kitchen appliances are durable, safe, and environmentally compliant.

Conclusion

Printed Circuit Boards are indispensable in the evolution of kitchen appliances. They serve as the technological backbone that supports intelligence, connectivity, safety, and efficiency in today’s kitchens. From simplifying everyday tasks to enabling advanced smart features, PCB are transforming the way we interact with cooking and cleaning equipment.

As innovation in electronics and IoT continues to grow, PCBs will become even more integrated, paving the way for truly autonomous, AI-driven kitchens. For manufacturers, consumers, and tech enthusiasts alike, understanding the role of PCBs in the kitchen is essential to appreciating and advancing the future of home living.

Keep an eye for more latest news & updates on Hamro Solarllc!